INDUSTRY OF THE FUTURE

Objectives

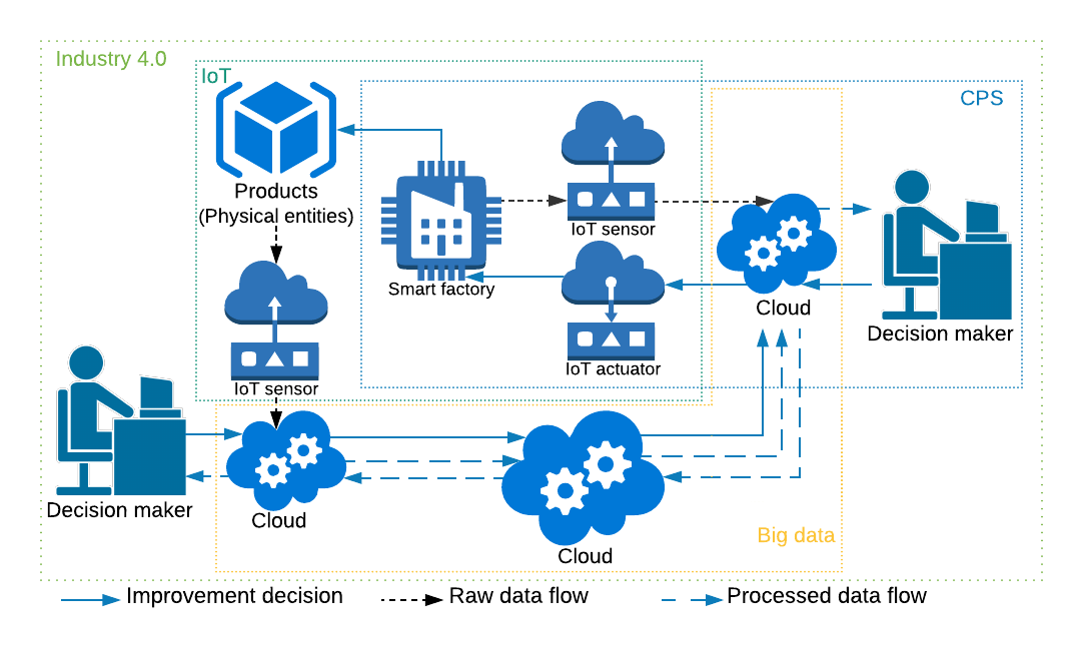

Industry of the Future (IoF), also called Industry 4.0 in Germany and Smart manufacturing in the USA, consists in outperforming the operational performances by transforming the production systems thanks to eight categories of disruptive digital technologies. Let us mention: collaborative robots and other intelligent machines (drones, AGVs), additive manufacturing, augmented reality and operator, simulations, horizontal and vertical integration of information, industrial internet, cloud and cyber security, big data and analyses.

Our research aim is not only to grasp the abilities of IoF technologies to, under certain conditions, disrupt the production management systems of companies, but also to gain knowledge on how to choose an adequate subset of IoF technologies towards efficient manufacturing system evolutions that are smarter, more flexible and more reliable. Our objective is also to bring consciousness to companies on how to manage their transformation. Numerous dimensions of the industrial model must be rethought, as:

- Transformation of business models and supply chains by digital solutions as blockchain technology and increased production flexibility,

- Modernization of the production tool,

- More integrated design, marketing, supplier and sales functions,

- Switching from mass production of standard products to mass production of more customized products,

- Lower resource and energy consumptions as well as wastes,

- Evolutions of man-machine interfaces and function allocations,

- Modernization of infrastructures management and operation.

|

|

|

In 2020

- The second edition of a 2-week International Summer School on Industry 4.0, that LGI co-organized in 2019 with ENS paris-Saclay and which should have been held in July 2020, has been cancelled due to the Covid-19 situation.

- CentraleSupélec and especially LGI are partners of the BCG (Boston Consulting Group) ICO (Innovation Centre for Operations) learning factory developed made to demonstrate the abilities of Industry 4.0 technologies to disrupt the production management systems of companies.

- Rongyan Zhou won the Canadian Mitacts Globalink Research Award for research in Canada. This allowed him to initiate research on the multi-tier supply chain theme with Concordia University.

- LGI is an active member of the Move In Saclay project (http://www.moveinsaclay.fr/) to improve the mobility experience of people on the “plateau de Saclay” using a digital twin to track people moves and propose co-sharing and mobility advices.

- Oualid Jouini participates to an international research project with Qatar University whose aim is to optimize the operations of the Doha harbor using the blockchain technology

- Safety and Risks LGI research group is leading a research activity on resilience of critical infrastructures through implementation of predictive maintenance. Three major French industrial partners are strongly involved in a 5-year chair to support this activity (EDF, SNCF, Orange).

KEYSWORDS

- Industry 4.0,

- Smart Manufacturing,

- Industrial Internet of Things (IoT),

- Cyber-Physical System (CPS),

- Cloud computing,

- Robotization,

- Simulation,

- Information systems,

- Cybersecurity,

- Additive manufacturing,

- Augmented reality,

- Machine learning,

- Connected systems,

- Predictive maintenance.